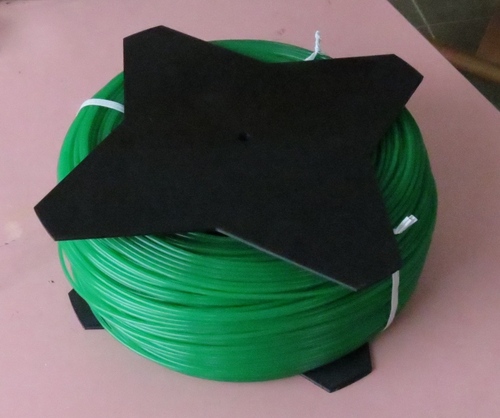

Spool for large coils of filament

Dec 15, 2013

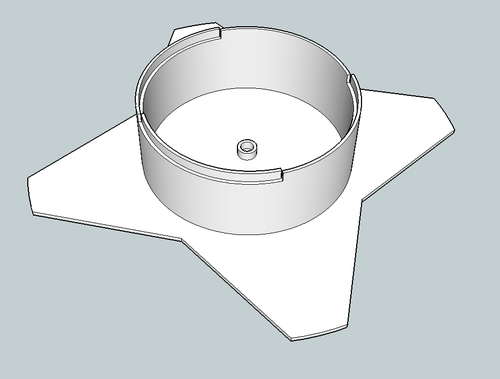

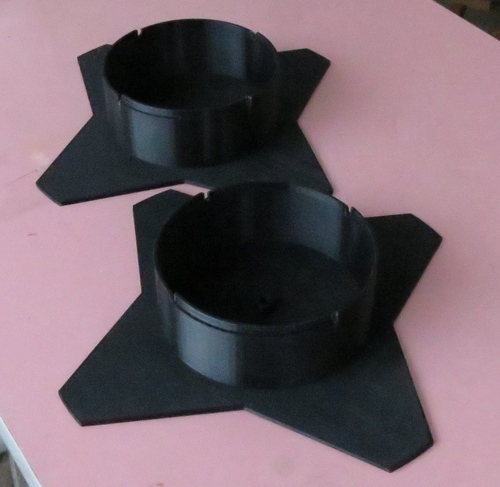

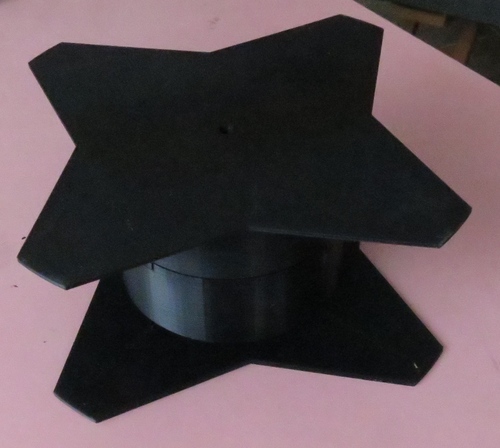

I usually purchase my filament in 1 kg reels, but recently had to purchase some in coils, some of which were 5 pounds. I had printed a two part reel in the past to deal with smaller coils, like this:

Work Bench for 3 Trinity Labs Aluminati

Dec 14, 2013

I ran out of horizontal work space when I purchased my third Aluminatus, so I had to come up with Plan B. I was going to build a work bench using two sheets of 4'x8’ MDF, cut down to 32", and a bunch of 2x4s. I’ve done this before, and the result is sturdy, but quite heavy, and the construction is time consuming. My friend Ray had another suggestion.

I purchased two 72" tall by 18" deep by 36" wide shelving units from Home Depot for $40 apiece. These units consist of 5 shelves and 4 sets of 4 posts to separate the shelves, along with 4 feet and 4 end caps. I used just 2 of the shelves and 2 of the sets of posts to create a structure that was about 36" tall (see the pictures); so, one of these units created two of these structures. And two of the structures could be used to support an MDF sheet as a work bench.

I used the spare shelves as templates and drew circles on the undersides of the MDF to indicate where the posts would meet the MDF.

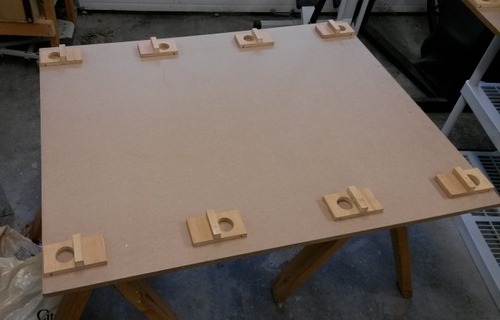

I then made some wooden post receptacles which I glued to the underside of some 40" x 48" MDF sheets, to accept the top of the posts. The result was two 40" x 48" benches, with shelving, for around $120.

Two of the shelving structures, ready to support the MDF sheets.